Fanuc Robotics Simulation Software Download

ROBOGUIDE® Robot Programming and Simulation ROBOGUIDE is the leading offline programming product on the market for FANUC robots. The ROBOGUIDE family of process. FANUC’s Dual Check Safety (DCS) control architecture includes safety functions in the robot cell to reduce floor space and make fenceless robots feasible.

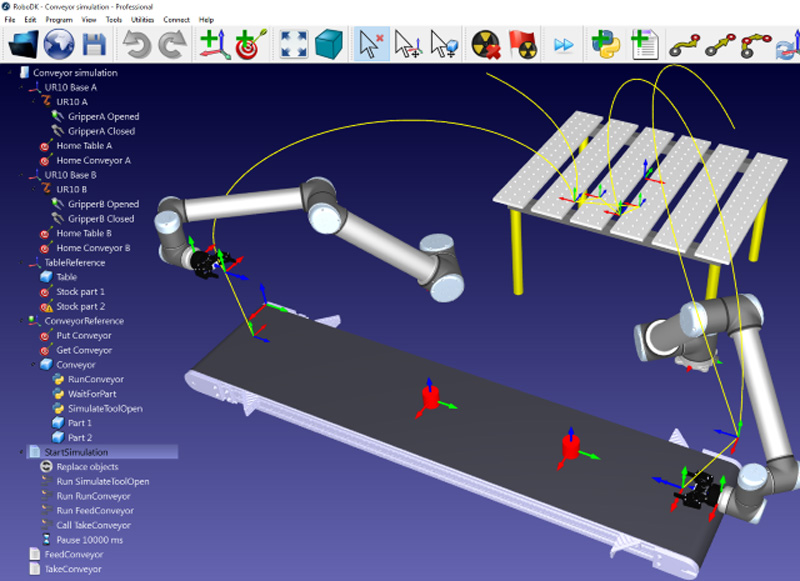

I feel really amazed about this development and I decided to use RoboDK for the KUKA robot, I am working with, in my company. I tried to install it on Ubuntu 16.04 (64bit), but I am struggling with an error message all day now (cannot find the Qt platform plugin “xcb” ). The latest python is installed and – as far as I know – all the Qt platform plugins required as well. I was unable to find any solution on the web or in the RoboDK-Forum – surely it’s a quite simple solution, but without help I will be unable to implement RoboDK for the upcoming tasks. Thanks a lot! This is very interesting to read! I’ve been programming ABB robots for about 10 years now and it is by far the easiest language I have had to deal with.

Fanuc is so clunky to work with, and you can’t edit it offline without a special program. Rapid feels very similar to Python. If memory serves I think Fortran was very similar.

Quaternions were ABB’s solution for a more compact method of solid body transformations as opposed to the more computationally intense homogeneous transform matrices. Maybe it’s because I’ve been using it so long, but I find it very easy to work with. 1,0,0,0 is when two coordinate systems are aligned in the XYZ axes. Very compact and efficient. The ABB is a programmer’s and mathematicians robot as far as I can tell. I stumbled upon your site because I am trying to find if anyone has figured out a way to run other manufacturers robots on different operating systems. I would love to see Rapid as the standard language.

I’m going to enjoy trying out your SDK! This a good explanation by you as i understand few of your technical words. Brusca and brusca invertebrates pdf file. Thanks for that Let me introduce myself. I am a robot teach pendent programmer fanuc abb etc. Also robot simulator and olp programmer of process simulate robcad roboguide etc. Well i dont know much about python c++ etc. Recently i came across a requirement of my customer where they need to program kuka robot for thermal spray coatings of turbine blades.

If you look at the turbine blades its having a very complex geometry and tricky to generate offline program, as you know process simulate or robcad is difficult for complex geometry for olp. My requirement is i need to generate kuka olp where as that software should be good enough to support complex geometries. Well i mean to say it should be very easy to generate robot paths using 3D cad native files. Hovc thermal spray is used in coatings for longetivity of materials. I can suggest your software to the customer but at the end its all depends on customer and the software easiness.

Hitmanpro trial reset. Thanks for your explanation. I am working on a Human-robot collaborative environment.

As I see in ISO 15066, the constraint for max velocity of the TCP, is enough in order to ensure safety, at least for free transient contacts (figure A.4). In ROBODK, there is the option to set linear constraints for a joint motion. Traditionally, a joint move is constrained by setting angular velocity and acceleration. In this way, it is most likely for the joint move to be faster than the linear one, and as I see, this is one of the reasons for someone to prefer joint to linear. So, is it ok to program a joint move with linear constraints (and not the angular constraints)? Thank you for your help!